SCI-Arc 學生發展出一套具有"undo"功能,生成自由形體的 3d printing 技術

SCI-Arc student develops freeform 3d printing with undo function

[寫在前頭]

關於Undo的說明,一直到看到影片最下面最下面的文字說明才知道意思"UNDO(resin removal via suction or scooping)"這技術是透過吸或舀的方式。

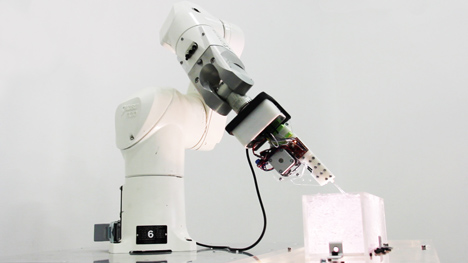

南加州建築學院的碩士生發展出一套方法,他們用一整缸的凝膠,運用機器手臂搭配3D Printing的方式,可以創作出不需要任何支撐材的自由形體,同時也允許做出"undo"的功能。

凝膠讓機器手臂擠出的液態樹酯固定並變硬,克服了其他3D Printing技術的缺點;避免了列印物件必須堆疊在自體上的限制。

|

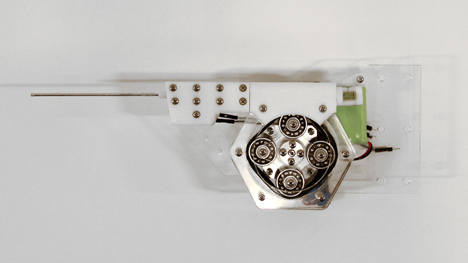

| Brian Harms 發明了一種特殊的列印工具 |

這樣的方式將允許基於向量資料的列印,意味著列印的噴頭可以三向度的移動,而不再需要依附在既有的二維堆疊架構物之上。

|

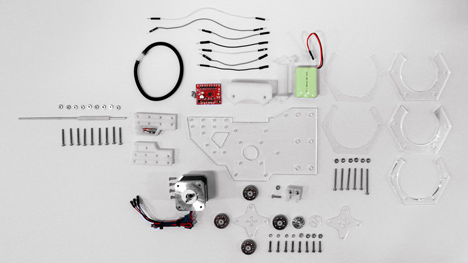

| 列印工具拆解圖 |

Brian Harms 發展出一套名為"懸浮定位(Suspended Depositions)"的處理方式,完成於他就讀 SCI-Arc 的 ESTm (Emerging Systems and Technologies)課程之中。透過注入與懸浮光固化樹酯(light-curing resin)於凝膠介質之中,不需要模具的、不用透過減法製造過程,一種新的自由成形方式。Harms 如此解釋這個方法。

|

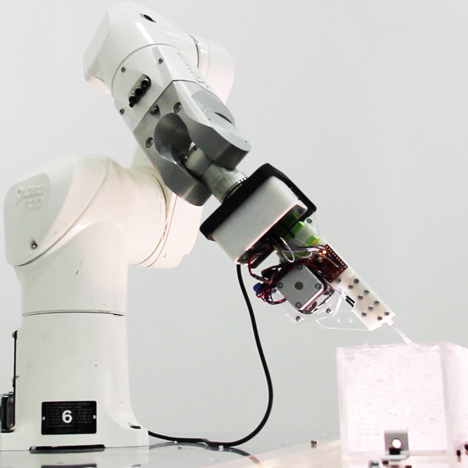

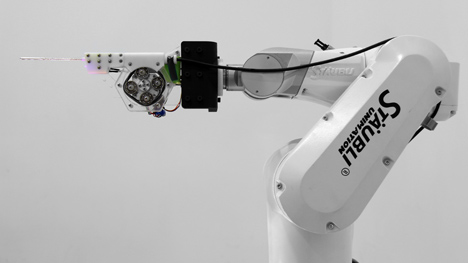

| 機器手臂與 Harms 發展出的嵌入式工具 |

光固化樹酯,透過 Harms 與其團隊研發出的特殊噴嘴(固定在機器手臂上),擠出後經過光照而硬化。當作品從凝膠中取出後,這些凝膠可以重複再使用。

|

| 機器手臂將光固化樹酯擠入一個充滿凝膠的容器裡 |

Harms 作品技術上的突破,延續了其他"自由形體"或是稱為"非支撐3D Printing"的技術。例如稍早五月,來自 Barcelona IAAC(Institute for Advanced Architecture of Catalonia)的 Petr Novikov 和 Saša Jokić 所發表的不用支撐材料的自由曲形,以及二月時可在空間中自由塗鴉的3D列印筆;該案在創投網站 Kickstarter 曝光的第一天就得到接近於五十萬美金(一千五百萬台幣)的募款。

|

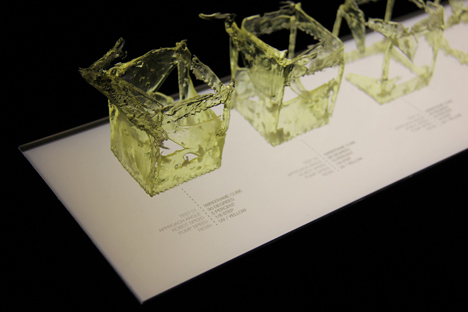

| 打樣測試 |

Here's some text from Harms:

Suspended Depositions

This project aims to blur the line between processes of design and fabrication in the context of rapid prototyping by increasing the fluidity of the fabrication process through coordinated material and robotic processes. The project exploits feedback loops that allow the process to be used as a live generative form-finding tool as well as a method for reification of designed objects.

By injecting and suspending light-curing resin in a gelatinous medium, one is afforded the ability to shape freeform objects without the need for molds or other subtractive manufacturing processes that would otherwise be necessary. The gel acts as an omnidirectional support material which is reusable, so there is no wasted material.

One major distinction between this project and other rapid prototyping processes is the ability to utilize 3D vector-based toolpaths. Virtually all other processes use paths generated via contouring a digital model, and rely on the hardening of each successive layer before being able to move on to the next.

The suspension of resin in space without added support material allows for the ability to navigate and fabricate directly on and around other existing objects within the Gel, as well as the ability to observe the process from any angle. The suspension of time in this process allows for tool changes, manual injections, on-the-fly robotic injections, multi-material injections, live modification of the digital or physical model, and the ability to physically "undo" (resin removal via suction or scooping).

Special thanks to Peter Testa, Brandon Kruysman, Jonathan Proto, Devyn Weiser, and Kyle and Liz Von Hassln.

SCI-Arc Fall 2012

Testa Vertical ESTm Studio

Instructor: Peter Testa / Brandon Kruysman / Jonathan Proto

AT: Peter Vikar

Project Lead: Brian Harms (nstrmnt.com)

Project Team: Haejun Jung / Vince Huang / Yuying Chen